Kemp Proteins’ Project Management Process

Client communication: Initial discussions and an ongoing collaborative communication process is vital to us maximizing the potential for your successful project outcome. Our initial discussions are information gathering to enable us to generate a statement of work, a “project plan”, that is shared with you. Together we refine the plan until the plan captures your project specifications and deliverables and nuances that may be particular to your protein of interest and its intended use. We will supply regular updates through conference calls or information download through electronic means such as “Box” or your preferred alternative.

Project Commencement: The project begins when we agree on the project specifications, and you provide us any client specific deliverables. Each project is different but runs to a general set approach.

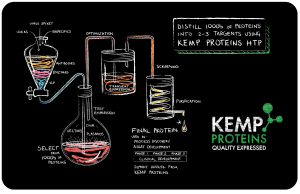

Project Approach: The USP is generally developed based on the clients preferred host and is supplemented with additional optimization to arrive at cost effective harvested quantity of the protein of interest. Our approach to specialty purification development is dependent on the project being undertaken. However, they all have certain commonalities. Using a recent project as an example we have outlined the steps for this project – other projects and resins have different steps. We have found this an efficient and effective process to achieve the desired outcome of our clients.

Start your scientific discussion today: request a quote.